Project Management at Desem Industries

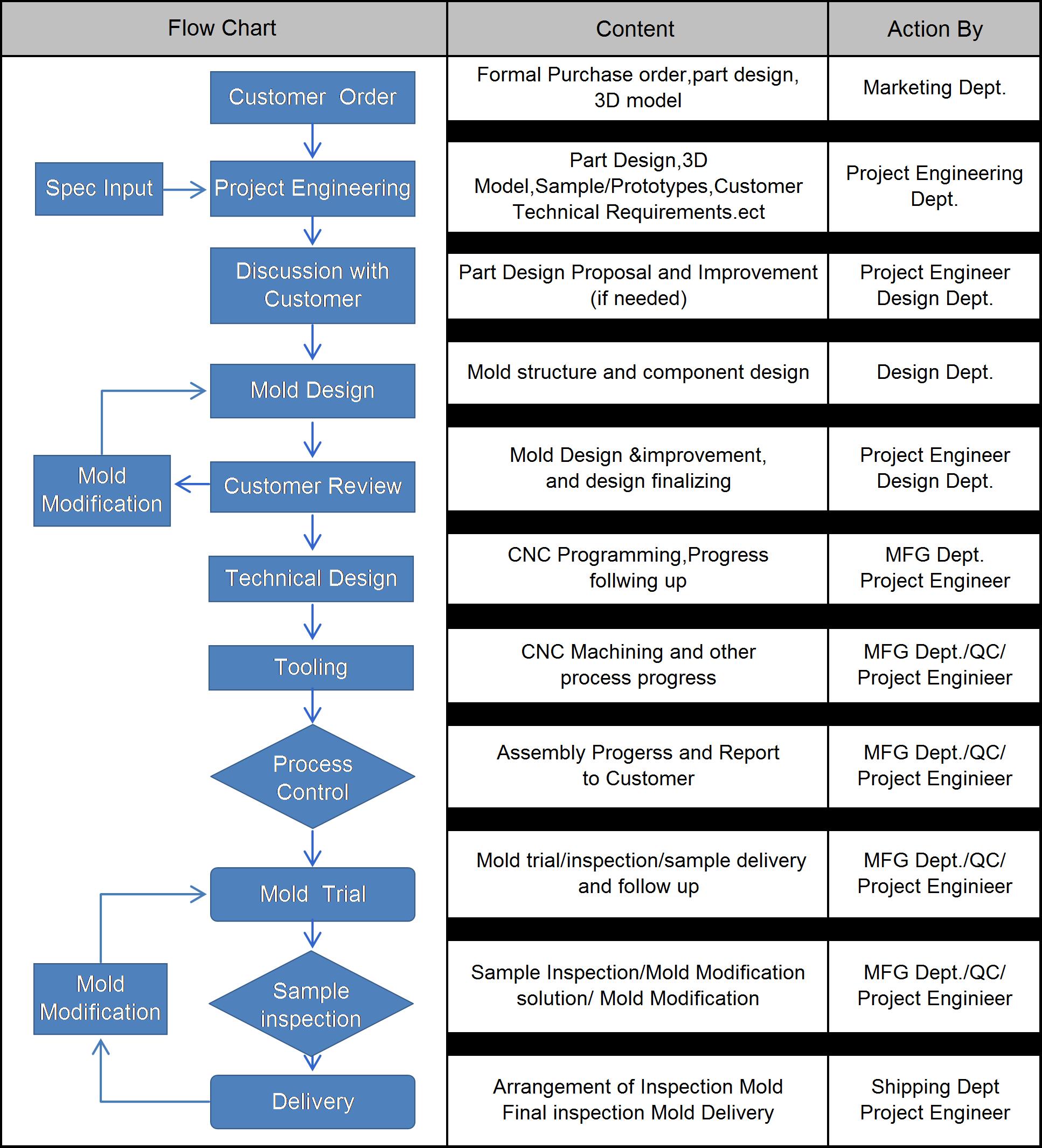

1> Series of engineering analysis will be carried out to your part drawing, including part &. mould structure analysis and Moldflow analysis etc..

2> Preliminary 2D&3D mould design normally takes 3-7 days.

3> Modify the mould layout after receiving your feedback, till your approval on the final design.

4> Based upon the approved full 3D mould design ,then order steel and mould base.

5> CNC programming will be followed immediately, and all the 3D component drawings will be transformed to 2D drawings with full mark of dimensions. All machining will be according to 2D component drawings.

6> A detailed time line report of the machining will be sent to you each week,with pictures to show you the mold progress& status.

7> Record the molding condition of T1(the first trial), take pictures and video of the process. After T1, we will send you samples, meanwhile a inspection report will be provided within 3-5 days.

8> After T1, our mould engineer will have a first mould checking . At the same time, we will improve the mould according to our inner review and any feedback from you. Latest samples and inspection report of T2/T3 will be sent to you for approval.

9> Your specific surface finish/texture will be done upon your approval on our sample,and sent the final sample to you for final approval.

10> Upon your final confirmation on OK sample, 1.For the moulds which stay in our workshop for further production, we will preserve it and wait for your production order .2 For the mould to be exported, we will have final mould checking/running according to the mould drawing and ship it to you by sea/air.

11> All documentation will be provided together with mould shipment: material certificate of core/cavity and mould base, heat treatment report(for harden steel only); 2D mould drawing in A1 printing; one CD with all 2D and 3D data; molding condition report & sample inspection report from final mould trial.